Your customers love the look of corduroy, but they worry it's too delicate for daily use. This hesitation costs you sales and limits your brand's reputation to just fast fashion.

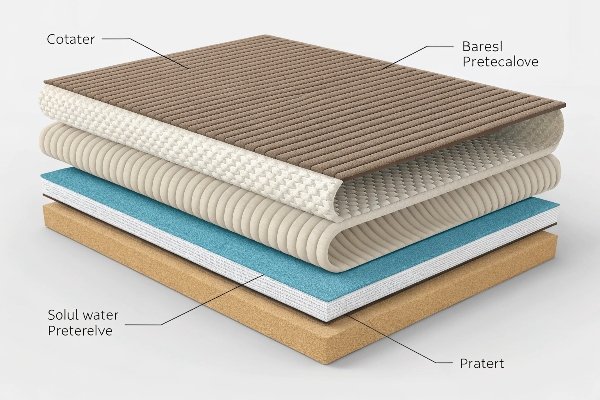

The secret lies in advanced manufacturing. By combining material science with precision engineering, we transform standard corduroy into a high-performance fabric. This includes fabric treatments, reinforced construction, and high-quality components, creating bags that are both beautiful and incredibly durable.

Since I started this business in 2005, I’ve heard the same concern over and over: "Is corduroy strong enough?" The truth is, the corduroy of today isn't the same as the fabric from the 70s. With modern technology, we can engineer it to be tough, water-resistant, and long-lasting. It’s not about magic; it's about a deep understanding of materials and a commitment to quality at every step. Let me show you how we build corduroy bags that defy expectations.

Is Corduroy Waterproof? Can Superior Manufacturing Provide the Answer?

A customer asks if your corduroy bag will survive a sudden downpour. If you say "no," you lose their trust. If you say "yes" without the right tech, you're setting them up for disappointment.

Standard corduroy is not waterproof, but ours can be. We use a unique fabric composite process to give our corduroy an IPX4 waterproof rating, protecting contents from rain and splashes without sacrificing the fabric's signature soft feel.

One of the biggest breakthroughs at our Guangzhou R&D center was solving this exact problem. Corduroy is made from cotton, a fiber that naturally loves to absorb water. A simple spray-on coating just won't cut it for a premium product. So, we developed a method to permanently bond a lightweight, flexible waterproof membrane to the back of the corduroy fabric. This process is a core part of our "Four-Fold Protection" standard. It gives the material an IPX4 rating, which means it’s verified to withstand water splashes from any direction. For your customers, this means the contents of their bag stay dry in the rain. For your brand, it means you can confidently sell a product that offers a real technical advantage, moving beyond just aesthetics. This is a key feature of our custom manufacturing services.

Are Zippers, Pockets, and Linings What Really Make a Corduroy Bag Sell?

A bag looks great on the shelf, but a week later the zipper breaks or a pocket seam rips. This single point of failure can destroy a customer's trust in your entire brand.

Yes, absolutely. While the corduroy fabric gets their attention, the quality of the details determines their satisfaction. Strong zippers, reinforced pockets, and durable linings turn a trendy purchase into a reliable favorite that earns positive reviews.

A bag is something people use every single day. They interact with the zippers, the pockets, and the lining constantly. These details are the true test of a bag's quality. In our Henan production facility, we operate under a strict ISO 9001 quality control system, which means we are obsessed with these small but critical components. We source smooth, reliable zippers that won't snag or break. At stress points, like the corners of pockets, we use reinforced stitching techniques like bar-tacking to prevent tearing. For the lining, we recommend materials like high-density nylon or polyester that are easy to clean and resist rips. Getting these details right on every single bag isn't an option; it's our standard. It's how we help you build a brand that customers trust and come back to.

How Does Material Science Help Us Craft Corduroy Bags That Actually Last?

Customers see corduroy as a soft, comfortable fashion fabric, not a durable workhorse. This perception can make them hesitant to buy, fearing the bag won't hold up to the demands of daily life.

We use material science to engineer corduroy for longevity. This involves selecting the optimal fabric weight, applying treatments for color fastness and tear resistance, and ensuring every batch meets our strict "Four-Fold Protection" quality standard.

Building a bag that lasts starts with the raw material. We don't just use any corduroy; we select the right specifications for the bag's intended purpose. But we don't stop there. We enhance the fabric's inherent properties through a series of treatments and quality checks. Our commitment to durability is codified in our "Four-Fold Protection" standard, a set of technical benchmarks every bag must meet. This scientific approach allows you to market your corduroy bags not just as stylish accessories, but as durable, high-performance products that customers can rely on day in and day out.

Our Four-Fold Protection Standard

| Protection Feature | Technical Standard | Benefit to the Customer |

|---|---|---|

| IPX4 Waterproof | Composite fabric technology | Keeps belongings safe from rain and splashes. |

| UPF50+ Sun Protection | UV-blocking fiber treatment | Prevents fabric color from fading due to sun exposure. |

| Grade 4-5 Color Fastness | Advanced dyeing process | Ensures colors won't bleed or fade with washing. |

| 300% Tear Strength | High-density weave selection | Resists rips and punctures from everyday use. |

Conclusion

True quality is born from technical expertise. By applying advanced manufacturing techniques, we create corduroy bags that are beautiful, incredibly functional, and built to last, satisfying both brands and their customers.